Unmasking the Truth Behind “One-Day” Concrete Coatings

In an article published in August 2020 by GarageFloorCoating.com titled, “Polyurea-Polyaspartic One-Day Systems: Do They Work“, the issues associated with these coating systems are examined. “1-day polyurea” or “1-day polyaspartic” garage floor coatings have gained significant recognition due to their easy application and labor/product cost-saving benefits…for the contractor. Moreover, customers find them desirable as they can be installed within a single day. However, it is crucial not to ignore the age-old wisdom of caveat emptor (let the buyer beware).

What’s a Polyurea and Polyaspartic?

Among professionals in the concrete coatings industry who value liquid coatings with quick-curing properties, polyureas and polyaspartics are excellent coating products that provide superior protection against UV radiation, chemical staining, abrasion and physical impacts. The terms “polyurea” and “polyaspartic” are often used interchangeably, but technically, the two products differ both chemically and in the speed in which they cure. “Pure” polyureas can cure in seconds…so quickly in fact, that application requires specialized equipment. A polyaspartic is similar to a polyurea, it’s called an aliphatic polyurea, but it has been chemically-modified to slow down its cure rate. Aliphatic polyureas (or simply, polyaspartics) have slowed-down cure rates so that they can be used efficiently to coat concrete – that is, with standard rollers, eliminating the need for specialized equipment. At the end of the day, however, even a polyaspartic is considered a quick-curing coating, relative to other coating types like epoxies and polyurethanes.

However, polyurea-polyaspartics products have one major “Achilles heel” – they simply aren’t designed for direct-to-concrete application and should never be used as primer coats, especially under conditions of high concrete moisture. Prudent contractors navigate around this issue by using a moisture-mitigating (slower-curing) epoxy as the primer coat and save the fast-curing polyaspartic as the topcoat only. ”1- Day” contractors can’t do this; if they used a slower-curing epoxy as the primer coat, they wouldn’t be able to apply their coatings in a single day as promised. So, instead, they downplay the value of epoxies (since they only have polyurea-polyaspartics in their arsenal) and fail to elaborate fully on the respective merits (and flaws) inherent in each coating type.

Merits and Flaws of Each Coating Type

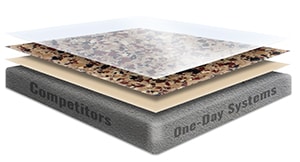

For example, “high-build” coatings like epoxies are excellent concrete primers because they can be applied thickly and mitigate against high hydrostatic pressures. However, because they tend to chalk and fade when exposed to UV light (sunlight), they’re lousy topcoats. Conversely, polyurea-polyaspartics are fantastic clear topcoats but, because they can only be applied thinly (due to the way in which they cure), they disappoint when used as direct-to-concrete coats; the wafer-thin coats fails to mitigate against high hydrostatic forces (that is, they delaminate!).

Advocates for “1-day” systems understand this dilemma and have “adapted” by including warranty exclusions within the customer contracts. These exclusions to “moisture-related issues” allow the 1-day contractor to bypass warranty claims resulting from moisture problems, including high hydrostatic pressure, thereby protecting themselves if and when peeling occurs.

Us Versus Them

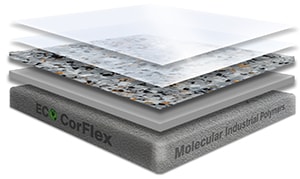

We use the inherent strengths of both epoxies and polyaspartics to create our floors. We use a moisture-mitigating epoxy as the primer coat (never a polyurea-polyaspartic), top it with your choice of over 50 full-flake color blends, and finish it off with two applications (not 1) of our clear 100%-solids polyaspartic topcoat. We are so confident in our 35 mils-plus thick flooring resisting moisture (including high hydrostatic pressures), staining (including hot-tire transfer), and automotive fluids, that we fully guarantee our coating systems. No warranty exclusions to “moisture-related issues” or staining.

These are the benefits of our flooring over any “1-day” system:

- We only use industrial-grade, 100%-solids liquid coatings in our full-flake garage floor coatings

- We prepare and then prime your concrete floor with our proprietary, moisture-mitigating epoxy primer (never using polyurea-polyaspartics direct-to-concrete)

- We offer both standard thermoplastic flake bends and over 30 mica-infused flake blends

- Our full-flake garage floor coatings are topped by 2 layers (not 1) of our clear 100%-solids polyaspartic

- We provide a full warranty against “moisture-related issues” and hot-tire transfer…no small print!

Want durable, commercial-grade garage floor coatings with a real warranty? Call us, Platinum Garage Flooring, at (941) 256-7124 to schedule your free, on-site estimate.